The heat-sealing production of the car seat lumbar support inflatable airbag is a delicate and critical process that ensures the airbag's sealing, durability and comfort. The following is a full step-by-step analysis of the process:

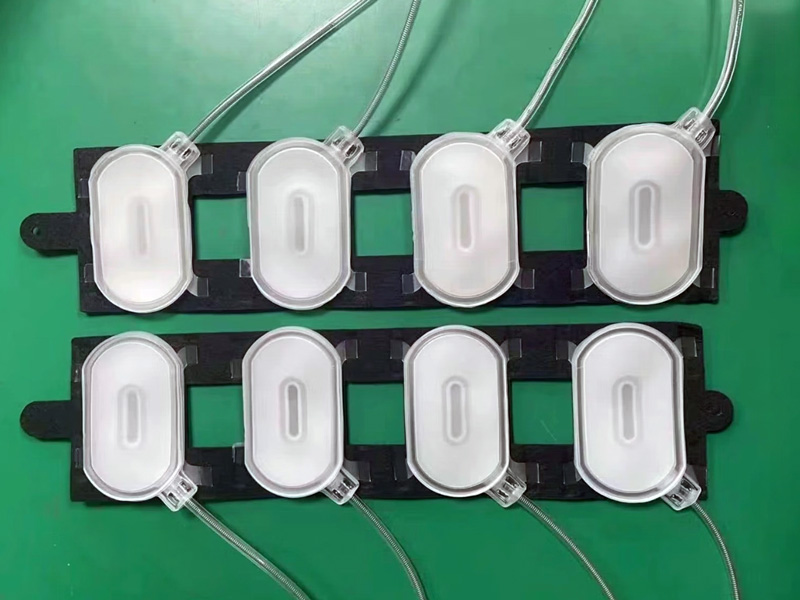

1. Material preparation

First, it is necessary to prepare materials that meet the design requirements, including fabrics and components of the airbag. These materials must meet the corresponding quality standards to ensure that the produced airbags have good performance and safety.

2. Material pretreatment

Before heat sealing, the materials need to be pretreated. This includes cleaning the surface of the material and removing impurities such as dust to ensure the heat sealing effect.

3. Design cutting

According to the product design requirements, use professional cutting equipment to cut the fabric into airbag parts of the required shape and size. This step needs to ensure the cutting accuracy to ensure the smooth progress of the subsequent heat sealing process.

4. Heat sealing connection

Place the cut airbag parts in the mold of the heat sealing machine, and melt and combine the materials at the airbag connection part by heating, applying pressure and holding for a certain time. Parameters such as temperature, pressure and time need to be strictly controlled during the heat sealing process to ensure the quality and sealing of the heat sealing.

5. Inflation test

After the heat sealing is completed, the airbag is inflated. Check the airbag's sealing and inflation speed and other indicators through inflation to ensure that the airbag meets the design requirements. If there are problems such as air leakage or slow inflation, timely adjustments and repairs are required.

6. Quality Inspection

After the inflation test is passed, quality inspection is carried out. Quality inspection includes a comprehensive inspection of the appearance, size, and sealing of the airbag to ensure that the quality and performance of the airbag meet the standards. Only airbags that pass the quality inspection can enter the next link.

7. Packaging and Delivery

After passing the quality inspection, the airbag is packaged and shipped. During the packaging process, it is necessary to ensure that the airbag will not be damaged or contaminated, and the product model, specifications, production date and other information must be marked on the packaging.

In general, the heat-sealed production of car seat lumbar support inflatable airbags is a process that requires strict control of every link. From material preparation to quality inspection, every step needs to ensure that its quality and performance meet the standards. In this way, a car seat lumbar support inflatable airbag with good sealing, durability and comfort can be produced.