1. Introduction

With the rapid development of the automobile industry and consumers' increasing attention to driving comfort, car seat massage airbags, as an important configuration to enhance driving experience, are gradually becoming the new favorite of the market. Its production technology is constantly innovating, which not only improves the performance and quality of the product, but also brings consumers a more comfortable and personalized driving experience.

2. Overview of car seat massage airbag production technology

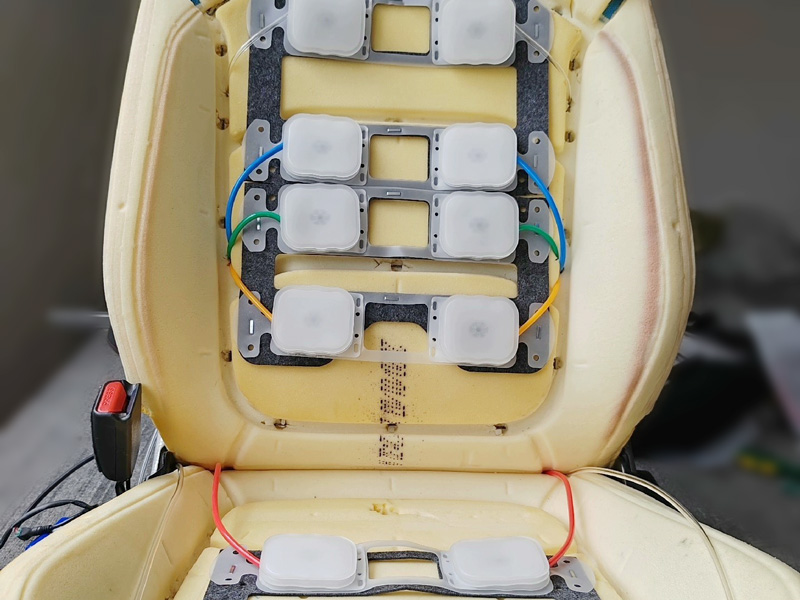

The production technology of car seat massage airbags mainly includes material selection, design and manufacturing, and function realization. Among them, material selection is one of the key factors, which is directly related to the durability, comfort and safety of the product. At present, the mainstream massage airbag materials on the market include TPU (thermoplastic polyurethane), etc. These materials have excellent elasticity, wear resistance and temperature resistance, which can meet the needs of different consumers.

3. Technical innovation points

Material innovation: The use of new polymer materials such as TPU improves the durability and comfort of massage airbags. At the same time, these materials also have good environmental protection performance, which is in line with the green development concept of modern society.

Design innovation: The three-layer highly retractable airbag design can be personalized according to the needs and preferences of the driver. This design not only improves the accuracy and comfort of massage, but also increases the fun and enjoyment of driving.

Functional innovation: Combine advanced sensor technology and artificial intelligence technology to realize intelligent control of massage airbags. For example, by monitoring the driver's physiological state (such as heart rate, blood pressure, etc.), the massage method and intensity are automatically adjusted to provide drivers with more intimate and personalized services.

IV. Production process optimization

The production process of car seat massage airbags includes material preparation, mold making, airbag molding, functional testing and other links. By optimizing the production process, production efficiency and product quality can be improved. For example, the use of advanced automated production lines and precise mold making technology can ensure the dimensional accuracy and shape consistency of airbags; through strict functional testing and quality control, the performance stability and reliability of massage airbags can be ensured.

V. Market application prospects

As consumers' requirements for driving comfort continue to increase, the market demand for car seat massage airbags is also increasing. In the future, with the continuous innovation of technology and further optimization of production processes, the performance and quality of car seat massage airbags will be further improved, and the market application prospects will be broader. At the same time, with the continuous development of technologies such as intelligence and networking, the functions of car seat massage airbags will become richer and more diversified, bringing consumers a more convenient and comfortable driving experience.

VI. Summary

As an important configuration to enhance the driving experience, the production technology of car seat massage airbags continues to innovate and develop. Through efforts in material innovation, design innovation, functional innovation, and production process optimization, the performance and quality of massage airbags can be further improved to meet the diverse needs of consumers. In the future, with the continuous advancement of technology and the continuous growth of market demand, the market application prospects of car seat massage airbags will be broader.