The material of TPU pneumatic lumbar support is mainly TPU (thermoplastic polyurethane). TPU is a polymer material with the following advantages:

Excellent elasticity and wear resistance: TPU material has good elasticity and softness, and can maintain stable performance at different temperatures. It is very suitable for making waist support airbags that need to be frequently inflated and deflated.

High wear resistance and toughness: TPU material can resist wear and deformation in daily use, ensuring the long-term stability of the airbag.

Welding machine for TPU pneumatic waist support

For the welding of TPU pneumatic waist support, a high-frequency heat sealing welding machine is usually used. The working principle of the high-frequency heat sealing machine is to use a high-frequency electric field to generate molecular motion inside the TPU material, thereby generating heat, so that the material melts and bonds together. When choosing a high-frequency heat sealing machine, production volume needs to be considered. For example, the double-slide push-disc high-frequency heat sealing welding machine has been favored by many airbag manufacturers due to its double-slide double-station number, automatic welding of finished products, and high efficiency and high yield.

Processing technology of TPU pneumatic waist support

The processing technology of TPU pneumatic waist support mainly includes the following steps:

Material preparation: Select TPU materials that meet the requirements, and cut and pre-process them according to the product design.

High-frequency heat sealing: Use a high-frequency heat sealing machine to weld the TPU material to form the airbag part of the lumbar support. During the welding process, parameters such as temperature, pressure and time need to be controlled to ensure the quality of welding.Catheter welding: Use a catheter welding machine to weld the inflation nozzle to ensure the stability and airtightness of the nozzle connection. Generally, the use of a high-frequency catheter welding machine can ensure the stability of the welding effect and effectively prevent the problem of air leakage.

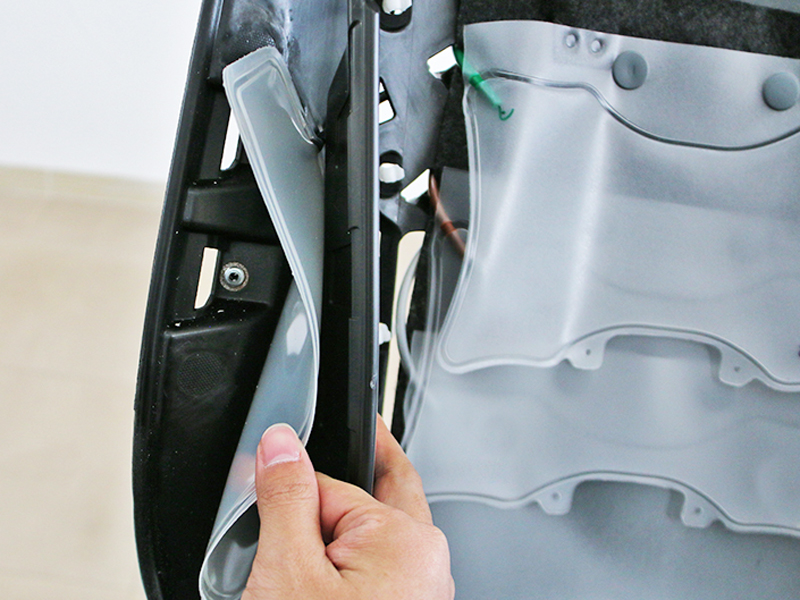

Assembly and testing: Assemble the welded airbag part with other components (such as air nozzles, control valves, etc.) and conduct quality inspection. The inspection content includes the airbag's sealing, inflation speed, support effect, etc.

Packaging and delivery: The pneumatic lumbar support that has passed the inspection will be packaged and prepared for shipment.

The material, welding machine and processing technology of the TPU pneumatic lumbar support are all key factors to ensure its performance and quality. By selecting suitable materials and equipment, and mastering the correct processing technology, TPU pneumatic lumbar support products with excellent performance and reliable quality can be produced.