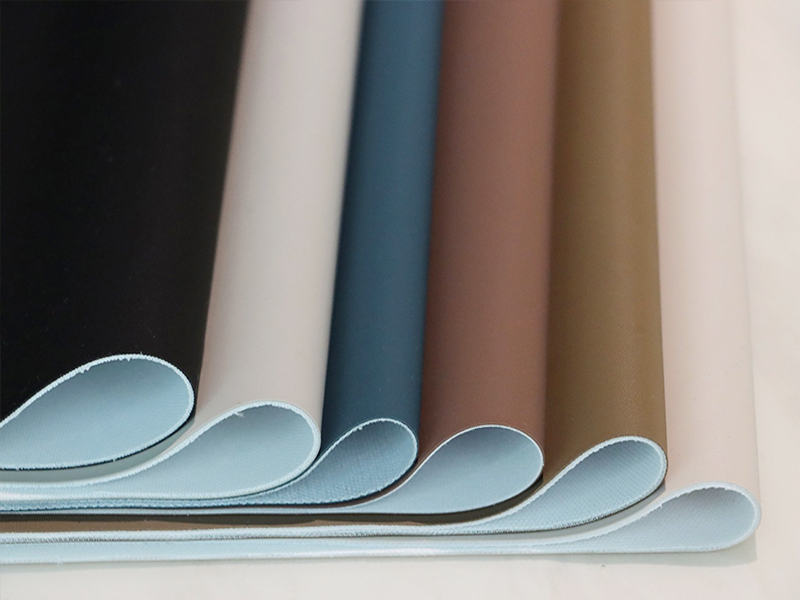

Recently, the world's first batch of sustainable silicone synthetic leather materials that can be mass-applied in transportation seats and interiors, home furnishings, fashion industry, smart wearable electronics and consumer electronics were officially released.

According to the reporter, at present, this new LUXSENSETM silicone synthetic leather has been successfully mass-produced in the field of car seats.

In this regard, Dow told reporters that this new LUXSENSETM silicone synthetic leather was first mass-produced and applied in the field of car seats because the fabric requirements for car seats are generally much higher than those for household items. It must have high wear resistance, UV resistance, hydrolysis resistance, easy cleaning, light transmittance, non-toxic and odorless characteristics. The unique molecular structure of silicone has reached a new level in terms of wear resistance, aging resistance, anti-fouling, flame retardancy, etc. It is wrinkle-resistant, easy to clean, has long-lasting performance, does not contain harmful solvents and plasticizers, and is odorless and non-volatile. It is very suitable for consumers of luxury car brands in terms of softness, moisture permeability, stability and environmental protection.

According to Dow's global traffic and transportation market director Jero Bello, "LUXSENSE TM silicone synthetic leather has excellent characteristics such as easy cleaning, no irritating odor, skin-friendly touch, and green environmental protection, which can achieve a balance between high-end and sustainable."

In fact, as early as August this year, LUXSENSE silicone leather has been first mass-produced in China and applied to HiPhi X, the first product of the domestic new car brand Human Horizons.

Earlier, in 2018, Dow began to work on the three major aspects of "sustainability, fashion and environmental protection" and began to move towards the upstream of the automotive industry chain. It has carried out joint efforts with some domestic car companies in safety structure, environmentally friendly interior, lightweight and other aspects, and developed various innovative environmentally friendly materials for use in new energy smart cars.

According to a reporter from Jiemian News, as of August this year, Dow's new environmentally friendly materials for the new energy vehicle industry have been implemented and put into use. In addition to silicone leather, it also includes innovative products such as acoustic foam and new TC series battery thermal conductive materials displayed at the third China Import Expo last year.

The person in charge of Dow Chemical told Jiemian News that many car companies have approached Dow for negotiations, hoping to cooperate on new materials such as silicone leather and apply them to new products and models.

"Both domestic and overseas OEMs have them. We have invested $300 million in the Zhangjiagang base to increase silicone production capacity. At the same time, the company will leverage its expertise in materials science to help create a low-carbon future for the world." The person in charge said.

According to reports, Dow Chemical has been continuously promoting more environmentally friendly ethane dehydrogenation and electrolytic cracking technologies for two years to significantly reduce carbon emissions from existing cracking units. According to Dow Chemical's carbon neutrality plan, net carbon emissions will be reduced by another 15% each year. By 2030, annual net carbon emissions will be reduced by about 30% from 2005 to 5 million tons, and carbon neutrality will be achieved by 2050.

The above-mentioned person in charge said: "This time, the first use of silicone leather materials on automobiles, especially the first mass production and application in the Chinese market, is based on China's future automobile market, especially the new energy automobile industry chain."