With the continuous development of the automobile industry, luxury car seats are no longer just a simple seat, but have become a key factor in improving the driving and riding experience. The introduction of innovative massage airbag technology has opened a new chapter for luxury seats, indicating that the future driving experience will move to a higher level.

Innovative massage airbag technology combines advanced material science, ergonomics and intelligent control systems to bring unprecedented comfort and functionality to the seats. These airbags are designed according to ergonomics and can accurately fit the body curve. By intelligently adjusting the inflation and deflation of the airbags, they can achieve massage and support for different parts of the body, effectively relieve driving fatigue and improve riding comfort.

When using high-frequency heat sealing machines to produce massage airbags for luxury car seats, the production process reflects a high degree of precision and efficiency. The following is a detailed introduction to the high-frequency heat sealing machine in the production of massage airbags:

Working principle of high-frequency heat sealing machine

The high-frequency heat sealing machine mainly relies on high-frequency electromagnetic fields to heat plastic materials so that the intramolecular friction reaches a hot melt state. Its working principle can be roughly divided into the following parts:

High-frequency power supply system:

The high-frequency power supply system is the core of the heat sealing machine. It is composed of modern IGBT transistors, power tubes and other components.

The voltage of the ordinary power supply is increased to hundreds of thousands of volts through a transformer to form a high-frequency electromagnetic field, and the frequency is usually around 27.12 MHz.

Heating system:

The heating system consists of high-frequency electromagnetic coils, electrode plates and pressing plates.

The high-frequency electromagnetic field passes through the heating coil, rubbing the material molecules, so that the material reaches a hot-melt state locally.

Pressing system:

The pressing system ensures that the heated and hot-melted materials can be quickly and evenly contacted and joined together.

It is usually composed of a pressing plate, an electrode plate and a manual/automatic pressing mechanism.

Application of high-frequency heat sealing machine in the production of massage airbags

Material selection:

Massage airbags usually use TPU (thermoplastic polyurethane) material because of its excellent elasticity and wear resistance.

Production process:

Cutting: According to the design requirements, use professional cutting equipment to cut the TPU material into a suitable shape and size.

Heat sealing: Place the cut material under the heating system of the high-frequency heat sealing machine and heat it with a high-frequency electromagnetic field to melt it.

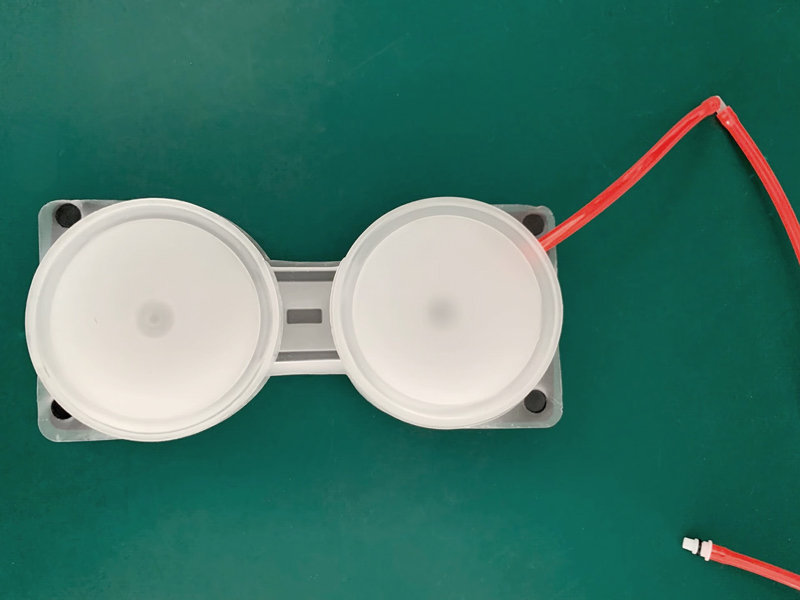

Laminating: Use the pressing system to quickly and evenly press the hot-melt material together to form the basic shape of the massage airbag.

Inflation test: Inflate the airbag after heat sealing to ensure that its sealing and inflation speed meet the design requirements.

Quality inspection: Comprehensive inspection of the appearance, size, sealing, etc. of the airbag to ensure product quality.

Advantages and features:

High efficiency: The high-frequency heat sealing machine adopts an automated production line, which greatly improves production efficiency.

Accuracy: Through PLC touch screen control, it is convenient to set parameters and achieve precise control.

Safety: The equipment is equipped with a spark protection device to ensure safety during the production process.

Adaptability: The high-frequency heat sealing machine can adjust the heat sealing parameters and processes according to different materials and designs, and has strong adaptability.

High-frequency heat sealing machines play an important role in the production of luxury car seat massage airbags with their high efficiency, precision and safety. With the continuous advancement of technology and the continuous development of the market, high-frequency heat sealing machines will continue to provide more possibilities for the automotive seat manufacturing industry.

The application of innovative massage airbag technology on luxury seats is not only a subversive innovation of traditional seats, but also a bold exploration of future driving experience. The application of this technology not only enhances the luxury and quality of the seats, but also allows drivers and passengers to feel meticulous care and care while enjoying the fun of driving.

With the continuous advancement of technology and the increasing diversification of consumer needs, innovative massage airbag technology will play an increasingly important role in the field of luxury car seats. In the future, we can expect more innovative technologies to be applied to bring drivers and passengers a more comfortable, healthy and intelligent driving experience.